Ple4Win

Ple4Win

Corkscrew in a wine bottle

And another addition to our ‘beyond the box’-category of application scope examples for Ple4Win…

See the starting page for more information.

Modelling a corkscrew, a cork and a (wine) bottle

Pulling a cork out of a bottle has been modelled using the Ple4Win program.

4 different models have been developed:

- Proper cork only

- Corkscrew + (proper) cork

- Corkscrew only in a proper cork

- Corkscrew only in an inferior cork

As it appeared to be impossible to obtain the required mechanical properties of cork, some cork pulling experiments have been carried out and some assumptions were made.

Assuming a proper cork, the property of interest when pulling a cork is the friction between the bottle and the cork.

In order to determine this friction corks have been pulled out of the bottle while measuring the pulling force.

Depending on cork and bottle the pulling force varies widely, but for this case a force of 12 kilogram has been taken from those measurements. The dimensions of the cork in question are: diameter 20 mm and length 50 mm, resulting in a friction cork-bottle of 0.04 N/mm2.

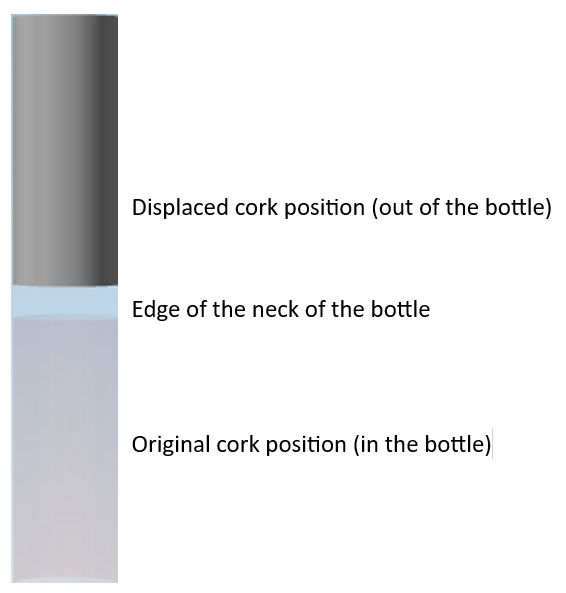

1. Proper cork only

The pipe model in Ple4Win has a diameter of 20 mm and a length of 50 mm.

The pipe model in Ple4Win has a diameter of 20 mm and a length of 50 mm.

The friction between cork and bottle has been simulated by firm soil.

The soil with ground level equal to top of pipe has a friction F = 0.04 N/mm2.

The results of the calculations are as follows:

| Pulling force (kg) | Vertical displacement (mm) | Number of iterations |

|---|---|---|

| 12.0 | 0.2 | 3 |

| 12.1 | 56.2 | 130 |

The screenshot above has been taken from the 3D Visualisation facility in Ple4Win.

The results show that for a pulling force > 12 kg the cork comes out of the bottle.

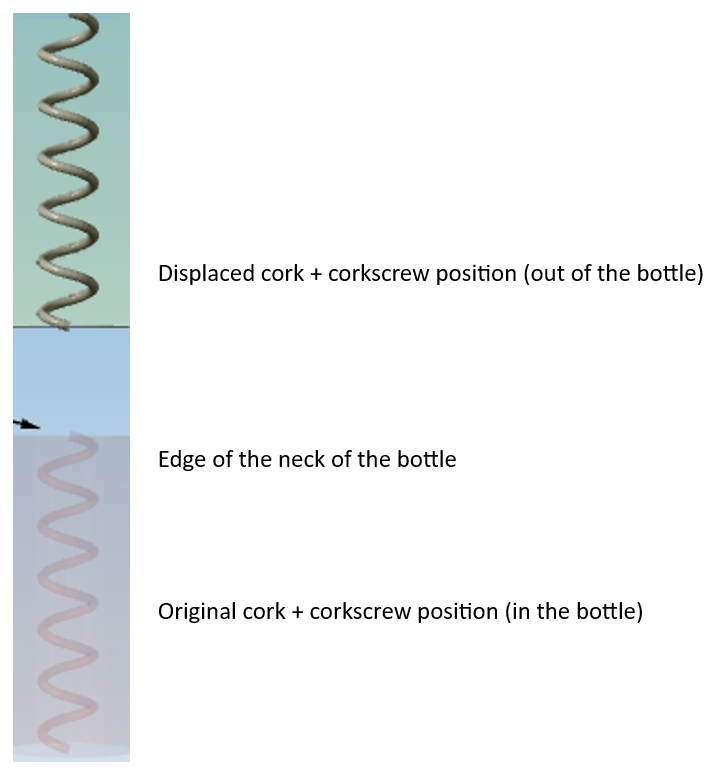

2. Corkscrew + (proper) cork

For this case, a SiS model has been specified in Ple4Win, consisting of an inner spiral pipe (the corkscrew) and an outer cylindrical pipe (the cork). The spiral and cylindrical pipes are rigidly connected at top and bottom. See the picture below.

For this case, a SiS model has been specified in Ple4Win, consisting of an inner spiral pipe (the corkscrew) and an outer cylindrical pipe (the cork). The spiral and cylindrical pipes are rigidly connected at top and bottom. See the picture below.

The soil with ground level equal to top of pipe has a friction F = 0.04 N/mm2.

The results of the calculations are as follows:

| Pulling force (kg) | Vertical displacement (mm) | Number of iterations |

|---|---|---|

| 12.0 | 0.2 | 3 |

| 12.5 | 64.8 | 40 |

The screenshot above again has been taken from the 3D Visualisation facility in Ple4Win.

Again, it turns out that for a pulling force > 12 kg the cork comes out of the bottle if the cork-bottle friction is 0.04 N/mm2 and the cork is of good quality. The iteration process for the SiS model is much faster than for the cork model treated before, however, the modelling of the SiS model is much more time-consuming.

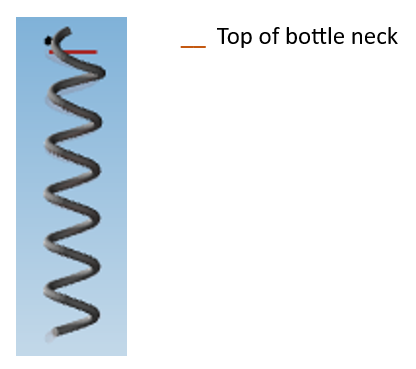

3. Corkscrew only in a proper cork

Only the corkscrew has been modelled as a spiral-shaped pipe. The cork is modelled as very firm soil with stiffnesses 1 N/mm3 in all directions and friction F = 0.04 N/mm2.

Only the corkscrew has been modelled as a spiral-shaped pipe. The cork is modelled as very firm soil with stiffnesses 1 N/mm3 in all directions and friction F = 0.04 N/mm2.

The results of the calculations are as follows:

| Pulling force (kg) | Vertical displacement (mm) | Number of iterations |

|---|---|---|

| 12.0 | 1 – 3.6 | 100 |

| 12.5 | 1.1 – 3.6 | 168 |

The model shows that the quality of the cork is good. The displacement of the corkscrew out of the cork is some mm’s only, so the corkscrew stays within the cork. But for P > 12 kg the cork comes out of the bottle according to the previous models.

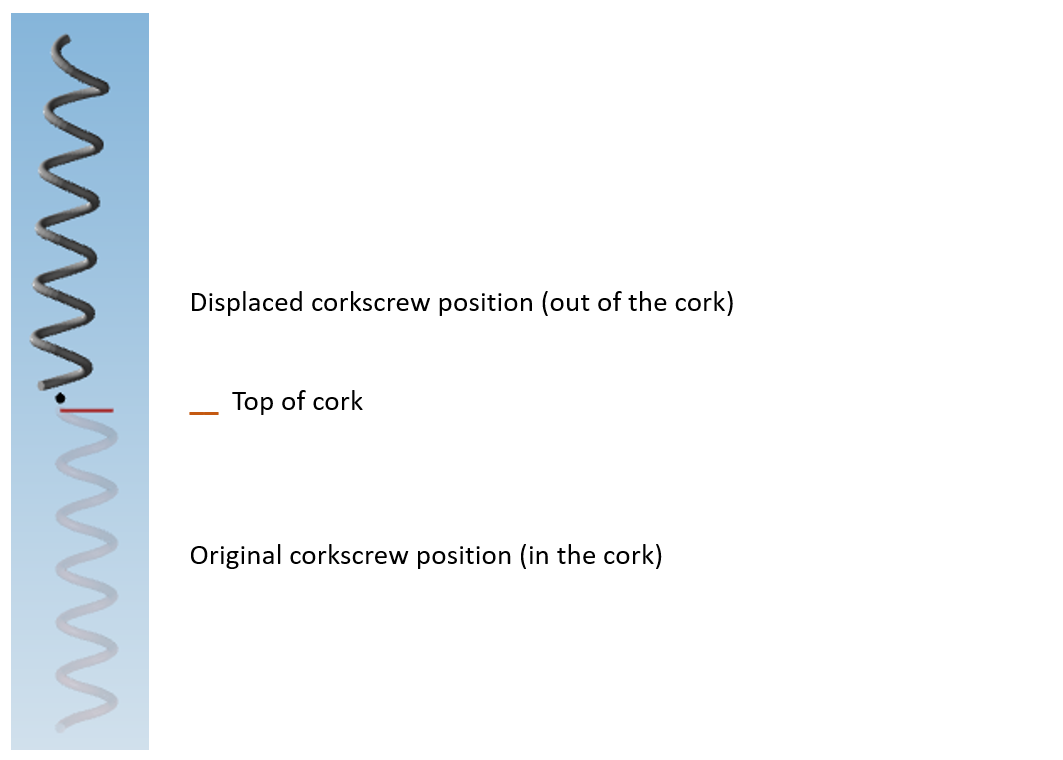

4. Corkscrew only in an inferior cork

Only the corkscrew has been modelled as a spiral-shaped pipe. The cork is modelled as weak soil with stiffnesses 0.01 N/mm3 in all directions and friction F = 0.04 N/mm2.

Only the corkscrew has been modelled as a spiral-shaped pipe. The cork is modelled as weak soil with stiffnesses 0.01 N/mm3 in all directions and friction F = 0.04 N/mm2.

The results of the calculations are as follows:

| Pulling force (kg) | Vertical displacement (mm) | Number of iterations |

|---|---|---|

| 12.0 | 51 – 56 | 50 |

| 11.5 | 50.8 – 52.3 | 100 |

| > 11.5 | > 50 | – |

The conclusion is that the corkscrew is pulled out of the inferior cork for a pulling force ≥ 11.5 kg. If the pulling force is < 11.5 kg, the cork stays within the bottle assuming that the friction cork – bottle is not less than 0.04 N/mm2.

The conclusion is that the corkscrew is pulled out of the inferior cork for a pulling force ≥ 11.5 kg. If the pulling force is < 11.5 kg, the cork stays within the bottle assuming that the friction cork – bottle is not less than 0.04 N/mm2.

For determination of the pulling strength of the spiral of the corkscrew one needs the following properties and data of the spiral steel: the diameter, the wall thickness, the modulus of elasticity and the yield and tensile strength.